Margarine Packaging Solutions & Machinery

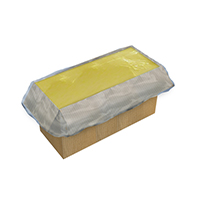

Increase Line Efficiency and Product Consistency with Reliable Packaging Technology. In a price-competitive fats and spreads market, margarine packaging plays a key role in protecting freshness, maintaining clean portion shapes, and ensuring a strong on-shelf appearance. Our range of automatic margarine filling and wrapping machines delivers accurate dosing for paste-like consistencies, consistent block forming, and tight, secure wrapping to minimize leakage and reduce waste. Built for dependable operation and easy maintenance, these solutions help you keep output high, downtime low, and every pack uniform from production to distribution.

Contact us now and get the most suitable offer for you!

Key Technical Features for Margarine Packaging

Precise volumetric

dosing

High-accuracy volumetric dosing ensures consistent portion weights for margarine and other paste-type products, minimizing product loss and ensuring clean brick formation.

Wide range of

portion sizes and shapes

Supports consumer-size portions from 10 to 25 g with quick weight changeover by adjusting brick height. Compatible with rectangular, stick, and semi-round brick formats.

Expandable

configuration

Optional central lubrication system and coding solutions (inkjet or thermo-printer) allow customization to meet production and traceability requirements.

Related equipment

Packages

Frequently Asked Questions

Can we pack butter, margarine, spreads, curd and other oils with the same machine or I have to have a separate machine for each product?

It is possible to pack on same Filling and Wrapping machine ARM for 10-25 g just butter and margarine.

Can we use packaging material with a design?

Yes, you can. Fasa butter Filling and Wrapping machine is using photocell centering device that packaging material would be cut evenly for each pack.

Can we easily integrate this machine to my already using processing line?

The Filling and Wrapping machine is a compact and can easily be integrated to processing and packaging line.

What are the possibilities for equipment shipment?

These are to be agreed – it varies up to the Customer’s needs according to Incoterms 2020.

It can be shipped by sea, air or roads. It can be delivered to the convenient Port for customer (CIF) or prepared to pick up from FASA warehouse (EXW). Variety of choices to be agreed.

What kind of package you are using for equipment shipment?

We are shipping our equipment in wooden package

Do you provide warranty and after sale service for your equipment?

We provide a warranty for all equipment we manufacture. To ensure reliable and long-term operation, we carry out the installation and commissioning of our equipment. Commissioning begins once the equipment has arrived at the customer’s facility and the site is ready for installation. During this process, our technicians train the customer’s staff in proper operation and maintenance of the machines. In the event of equipment failure, we supply the required spare parts and provide after-sales service.

Do you provide spare parts?

We supply a set of spare parts sufficient for one year of operation and offer the option to purchase a spare parts set for two years. The standard spare parts set includes sealing rings, gaskets, bearings, springs, and similar components. This allows customers to replace parts quickly and easily.

Any additional spare parts can be supplied by FASA as required. We also offer upgrades and improvements for previously manufactured machines. As FASA machines are developed by our in-house R&D team, after you give us an ID of your machine, we are able to provide customers with additional options and technical upgrades.

Contact us now and get the most suitable offer for you!