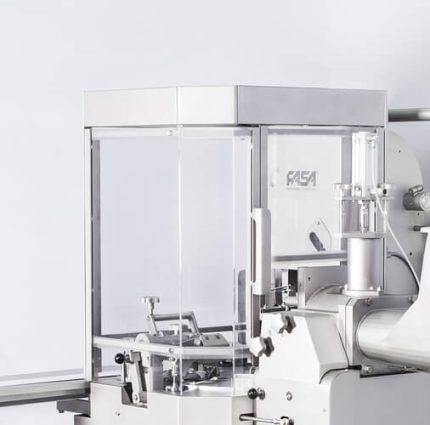

ARM - Butter filling and wrapping machine

Butter wrapping machine – ARM is designed to fill and wrap butter, margarine, etc. into aluminum foil, parchment paper or ecoline (with memory).

Main features

- Packing paste type products into consumer size portions.

- Applicable products: butter, margarine, spreads, edible fats, curd.

- Type of dosing – volumetric.

- Two product feeding options: hopper with augers or direct feed from the production line via resting tube.

- Machine’s output: 80 packs/min;

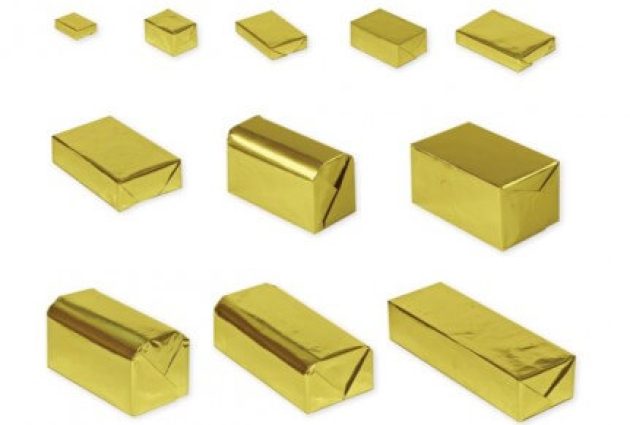

- Sizes of package: 10 – 25 g.

- Possibility to shift between portion weight by changing the height of brick.

- Shapes of bricks: rectangular, stick or semi-round.

- Folding type of package: bottom folding.

- Product input temperature: butter +10….+14 °C, margarine +8….+14 °C.

- Packaging materials: laminated aluminum foil, parchment paper, ecoline (with memory).

- PLC and HMI with Touch Screen.

- Pneumatic compensator.

- Stainless steel dosing unit.

- Stainless steel rotary table with synthetic inserts.

- Machine body covers from stainless steel.

- Machine safety covers.

- Sensor for foil tracking.

- Foil centering device with photocell.

- UV lamp.

- Central lubrication system (optional).

- Possible printers (optional): Ink jet, Thermo-printer or Cold emboss coding unit.

Contact us now and get the most suitable offer for you!

Video

Benefits

RELIABLE PACKING MACHINE

The base model ARM machine has been in production for more than fifty years and is of a proven design. More than 8 300 models have been delivered worldwide. By acquiring experience, constantly improving the design of the machine, we achieved optimally simplified and reliable technological solutions that allow to operate and maintain the equipment easily and to meet the needs of a modern dairy plant.

WIDE CHOICE OF BRICK SIZES AND SHAPES

Wide range of bricks sizes and shapes: the ARM machines fill and wrap traditional rectangular bricks, semi round and stick shape portions with bottom folds. A possibility to pack different sizes using a single machine by adjusting the height of the brick. Machine’s output depends on the brick’s weight and can vary from 15 to 80 packs / min.

ACCURATE DOSING

The machines fill and wrap such products like butter, margarine, edible fats, curd or other products of paste type consistencies with a certain filling level. The dosing device accurately fills the formed bricks avoiding a product leakage.

INTEGRATED SOLUTION

Improvement of packing by the integrated end of the line solution: semi-automatic case packer DSU is available for the end of the line packaging into cartons.