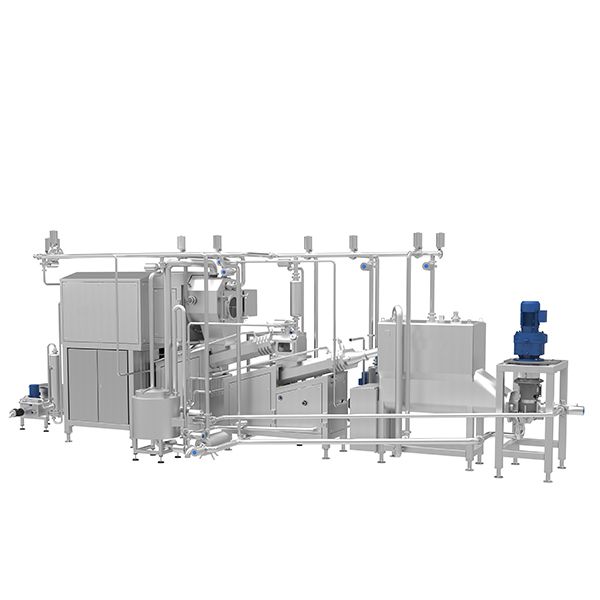

Butter processing line

Butter production line for butter production produce a first-class product with great care with best spreadability and moisture distribution. Fully compatible with ARM and EMF series packing machines.

Main features

- We produce complete butter processing lines, from cream tanks to end packaging equipment;

- Butter Making machines for 10 000 kg of butter per hour;

- Butter Batch Production machinery up to 5000 l of cream;

- With our Continuous butter making machines you can produce not only butter, but also different kinds of spreads;

- Low fat content of butter milk: 0,5%;

- Long shelf-life of the final product;

- Our butter making lines are user-friendly, compact and easy to maintain.

Contact us now and get the most suitable offer for you!

Benefits for your dairy experience

Not only for butter

Using butter making machines, you can produce not only butter, but also different kinds of spreads. For the product with fat content 72,5% -82,5% no stabilizers and emulsifiers are needed. You can also produce low fat spreads, using stabilizers and emulsifiers, with min fat content 50%.

Has different dosing units

Butter making machines can be equipped with different kinds of dosing units: for moisture, culture, oil (for spreads production), dry ingredients (mushroom, herbs, cacao etc) and salt slurry. Moisture level can be measured and controlled automatically with a special moisture metering system.

Can go directly to packaging machine

Butter produced with a continuous butter maker can go directly to a wrapping or bulk extruding machine or can be fed with a butter pump first to a butter silo of the required capacity, and then to the packaging machines.

Smaller capacity butter-makers are available

Smaller capacity butter-makers (up to 200kg per hour) which can be used both for the lab and also actual butter production purposes are available.

Long shelf-life

Butter and spreads produced by butter making machines have long shelf-life. In order to ensure that, our continuous butter makers are equipped with a vacuum chamber for pressing air (which may cause bacteria contamination) out of the product. Also, special construction of the machine prevents sticking the product to any inner surfaces of the equipment. After the CIP cleaning is finished, no traces of water can be found inside the machine.

Stable quality characteristics

Butter making machinery produces product with stable quality characteristics, which can be adjusted easily at the PLC operation panel during butter production. The final product has high temperature resistance and spreadability, with fine moisture dispergation. Butter-milk fat content is very low, down to 0,5%.

User-friendly and integratable to existing lines

EGLI butter making lines are user-friendly, compact and easy to maintain. We can integrate our butter-making machinery into your existing processing line or offer you a complete production solution, from the tanks for cream storage and ripening, to all kinds of packaging machines, like wrapping machines and case packers, bulk extruder, cartooning machine, bulk filler, bag sealing and closing machine, bulks and plates multiformat machine, cup fillers etc.